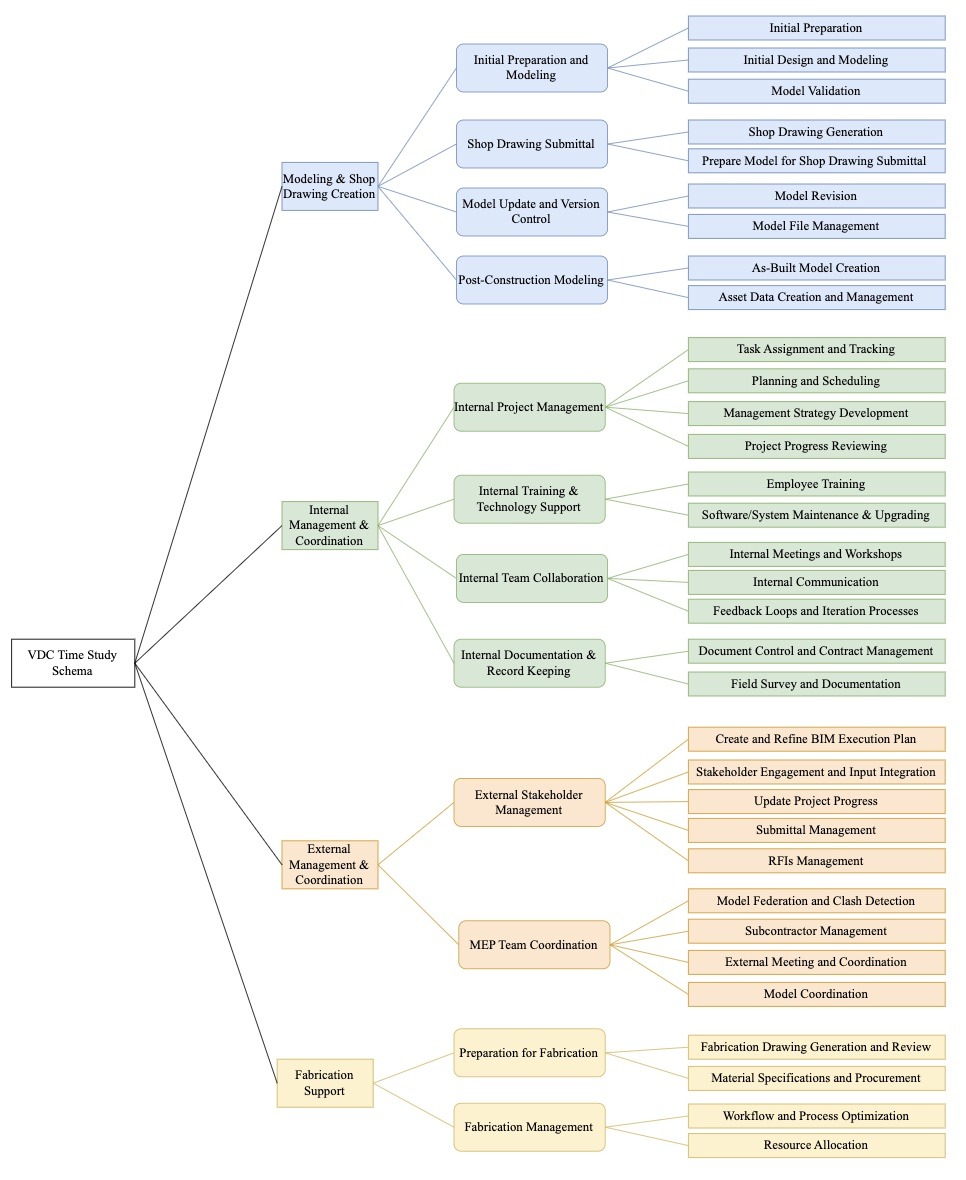

This schema provides a comprehensive overview of the various activities involved in VDC, categorizing them into key areas such as Modeling & Shop Drawing Creation, Internal Management & Coordination, External Management & Coordination, and Fabrication Support. Each category further details specific tasks and processes, offering a structured approach to understanding VDC workflows and scopes. Brief explanations of the schema can be found below the schema diagram. For detailed explanations of the schema and the development process, please refer to the paper.

1. Modeling and Shop Drawing Creation (Creating, validating, and managing digital representations of the project’s physical and functional characteristics)

-

- Initial Preparation and Modeling (Creating new models)

- Initial Preparation (Setting up the modeling environment, including reviewing contractual documents, understanding modeling specifications, and establishing a computerized environment including shared data platforms, grid lines, and file organization systems. For the BIM execution planning, please refer to Create and Refine BIM Execution Plan)

- Initial Design & Modeling (Creating and converting of preliminary models based on the project’s design intent and contract documents)

- Model Validation (Ensuring the accuracy and completeness of the developed model against the intended design)

- Initial Preparation and Modeling (Creating new models)

-

- Shop Drawing Submittal

- Shop Drawing Generation (Generating shop drawings, producing detailed drawings, and adding annotations, dimensions, and tags to these documents)

- Prepare Model for Shop Drawing Submittal (Preparing a digital model to be submitted as shop drawings. It includes finalizing the design details, annotations, and any necessary specifications within the model to ensure it meets the required standards and accurately represents the construction or manufacturing details needed for approval or further processing)

- Model Update and Version Control (Making modifications to a digital project model and systematically managing its multiple versions to track changes, preventing data loss, and ensuring that team members are working with the most recent and accurate representation of the project)

- Model Revision (Making necessary modifications to the model to reflect any design changes; this can be due to RFIs, design change, or 3D coordination)

- Model File Management (Managing files and security including file backups)

- Shop Drawing Submittal

-

- Post-construction modeling

- As-built model creation (Updating models to reflect the project’s final constructed state for documentation purposes)

- Asset Data Creating and Management (Establishing and maintaining a record of assets, along with their specific characteristics, such as brand, model, and serial number)

- Post-construction modeling

2. Internal Management & Coordination (Addressing the organizational aspect of a project, including internal operations and external stakeholder interactions)

-

-

-

- Internal Project Management

- Task Assignment and Tracking (Assigning responsibilities and tracking the status of project tasks)

- Planning and Scheduling (Setting up and organizing the project timeline and milestones)

- Management Guidelines (Establishing standard procedures for the project, such as change order review and work permit review procedures)

- Project Progress Reviewing (Evaluating the project’s progress and direction by examining factors such as completion percentage, time invested, and remaining budget)

- Internal Project Management

-

-

-

- Internal Training & Technology Support

-

-

- Enhance Employee Proficiencies by Providing Regular Training Sessions (Offering educational sessions to improve worker capabilities and skills. Including both formal and informal peer-to-peer training)

- Software/System Maintenance & Upgrading (Ensuring tools and systems remain functional and upgrading if necessary to enhance the system stability)

-

-

- Internal Team Collaboration

-

-

- Meetings and Workshops (Organizing and attending sessions for brainstorming and decision-making)

- Internal Communication (Spending time on team communication, such as writing emails or having phone calls)

- Feedback Loops and Iteration Processes (Revising and refining every aspect of the project based on team feedback)

-

-

- Internal Documentation & Record Keeping

-

-

- Document Control and Contract Management (Managing and maintaining important project files such as design coordination, meeting minutes, and contract control, not including models and drawings)

- Field Survey and Documentation (Conducting site observations and capturing field data including but not limited to project progress, conditions, and compliance)

-

3. External Management & Coordination (Managing interactions and aligning efforts with external stakeholders such as clients, consultants, subcontractors, and third parties)

-

- External Stakeholder Management

- Create and Refine the BIM Execution Plan ( Planning the essential prerequisites for modeling, delineating the roles and responsibilities, and securing the necessary clearances for the modeling activities within the framework of a BIM execution plan)

- Gathering Feedback and Concerns (Collecting input, opinions, critiques, and concerns from stakeholders regarding a project including requirements from stakeholders that might cause a design change)

- Update Project Progress (Managing project schedules and informing stakeholders about the project’s status. This can be a formal meeting, email, or phone call)

- Submittal management (Addressing issues related to submittal and the time to solve the problems)

- RFIs management (Writing and responding to RFIs and any other interaction with external people)

- MEP Team Coordination and Collaboration

- Model Federation and Clash Detection (Federating different models, such as plumbing, electrical, and HVAC, into a shared model environment and identify all clashes; does not include the model revision caused by clashes – see Model Update and Version Control)

- Subcontractor Management (Overseeing subcontractor performance and ensuring alignment with project standards)

- External Meeting and Workshop (Setting up and participating in gatherings aimed at generating ideas and making decisions)

- Model Coordination (Collaborating on modeling with external parties, including integrating third-party models or data into the main project model, Clash Detection, and ensuring third-party compliance with project standards and requirements

- External Stakeholder Management

4. Fabrication Support (preparing, managing, and integrating information for the manufacturing of the project components)

-

- Preparation for Fabrication

- Fabrication Drawing Generation and Review (Producing detailed diagrams for fabrication and installation and coordinating with manufacturers)

- Material Specifications and Procurement (Defining materials, work packages, creating material lists, and calculating material quantities)

- Fabrication Management

- Workflow and Process Optimization (Creating an optimal process and timeline to fabricate materials and deliver them to the right place)

- Resource Allocation (Manpower, Machinery, Materials) (Allocating manpower, machinery, and materials to ensure execution as planned)

- Preparation for Fabrication

The introduction of a standardized VDC task schema demonstrates the potential for standardization across the construction industry as it continues to adopt and mature the VDC processes. By offering a common framework to define, classify, and name VDC activities, this schema addresses one of the industry’s persistent challenges––variation in task definitions and inconsistent terminology.

First, the VDC task schema lays the foundation for industry-wide standardization of VDC task structures. It reduces ambiguity in how teams and companies define and describe modeling, coordination, and planning activities. A consistent vocabulary can streamline collaboration, enhance training and onboarding, and reduce miscommunication across trades.

Second, the schema enables companies to track and analyze the time invested in each VDC activity with greater clarity. By aligning internal task lists with a standardized structure, organizations can better understand how time is distributed across different functions. This insight is critical for informed resource allocation, performance assessment, and continuous workflow improvement.

Finally, a shared schema opens the door for industry benchmarking. When multiple firms adopt the same activity structure, meaningful comparisons can be made across projects, allowing for identification of best practices, inefficiencies, and strategic areas for improvement. Over time, this can drive collective progress across the sector and support the creation of data-informed guidelines for VDC implementation.

To fully leverage the benefits of the VDC task schema and accelerate its impact across the construction industry, we offer the following recommendations:

1. Integrate the Schema into Time-tracking and Project Management Tools

To realize the benefits of improved time and resource allocation, organizations are encouraged to incorporate the schema into their digital tools. Using standardized task schema in time-tracking systems enables accurate measurement of effort spent on specific VDC activities and allows for insights into performance across the schema tasks.

To successfully integrate this schema into time management systems, we recommend initiating a change management process. This includes assessing the impact on existing systems, identifying the organizational adjustments required, and providing adequate training and support to employees to ensure a smooth transition and sustained adoption. Additionally, if your organization does not currently have a time-tracking process or lacks an effective tool for this purpose, we recommend exploring user-friendly solutions such as Clockify, a time-tracking platform we tested as part of this study. Other options include Toggl Track, Harvest, or TrackingTime.

2. Use the Schema for Training and Onboarding

Once the schema is integrated into organizational processes, it is essential to provide regular training for both new and existing employees. Given that the adoption and refinement of the schema will require sustained effort over time, ongoing training ensures that all team members are informed about the latest updates and are equipped to use the system accurately, particularly for reliable time-tracking.

Standardized activity definitions can also streamline the onboarding process, helping new employees and collaborators quickly understand VDC workflows and reducing confusion during project execution. Incorporating the schema into training programs fosters a shared understanding across teams and supports consistent implementation.

3. Facilitate Industry Collaboration and Knowledge Sharing

Industry associations, project partners, and all other interest groups should consider adopting the schema as a shared framework for benchmarking. Common definitions enable stakeholders to compare project performance, develop collective best practices, and track industry progress over time.

4. Refine and Expand the Schema Through Continued Feedback

As companies begin to adopt the schema and apply it across diverse project contexts, we admit that refinements may be necessary to ensure its continued usability and relevance. The initial version of the schema was developed with input from a limited number of companies and may not fully reflect the needs of the broader industry. We welcome and encourage ongoing improvements based on real-world application.

If modifications or expansions are needed, we recommend keeping a clear record of the changes made, along with documentation of the specific context or project circumstances that prompted them. This transparency will support possible justification and future knowledge sharing with the industry.

In addition, we encourage companies to further develop more granular task definitions as needed. While the current schema defines tasks up to Level 3, project teams may find value in breaking these down into more detailed sub-tasks tailored to their specific workflows.