The construction industry’s increasing reliance on Virtual Design and Construction (VDC) has created a growing need for standardized benchmarking metrics to evaluate performance, allocate resources, and inform strategic planning. While the development of a national benchmarking system is a promising goal, achieving it will require ongoing collaboration between industry and academia. This section presents the results of a foundational study conducted by the University of Washington, in partnership with over 25 companies and industry associations, to explore current VDC practices and propose a path forward.

VDC Activity Schema Development

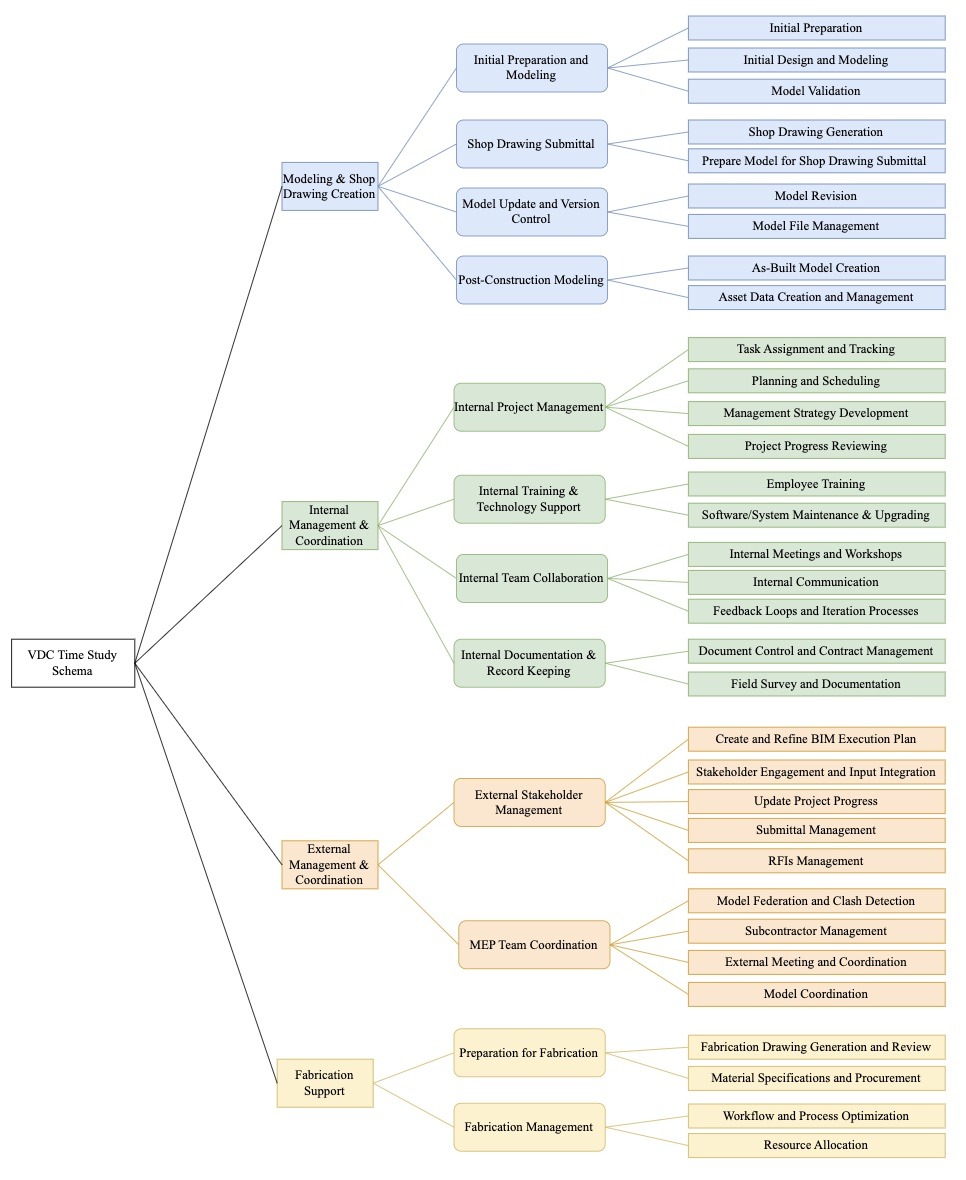

VDC Activity Schema

Industry Implications

- Standardization: The VDC activity schema provides a consistent framework to define and categorize tasks, reducing ambiguity and improving communication across the industry.

- Time Tracking: Aligning internal practices with the schema enables clearer time tracking, helping organizations analyze resource use and optimize workflows.

- Benchmarking: A shared schema allows for meaningful comparisons, supporting benchmarking and the identification of best practices both within and between companies.

Practical Recommendations

- Integrate into Tools: Incorporate the VDC activity schema into time-tracking and project management systems to enable consistent measurement and performance improvement.

- Training and Onboarding: Use the schema as a foundation for training and onboarding to ensure consistent understanding and accurate application across teams.

- Collaboration and Benchmarking: Encourage industry-wide adoption of the schema to support cross-company benchmarking, knowledge sharing, and best practice development.

- Ongoing Refinement: Continuously refine and expand the schema based on real-world feedback, and document changes to support transparency and future improvements.

Task-Role-Responsibility Mapping

Unpacking Task-Role Dynamics in VDC Practice

- Relationship between Roles: The detailer and manager exhibit shared working relationship, while the coordinator takes on a more independent role across all task categories

- Responsibility Patterns of Roles: The roles of coordinator, detailer, and manager show consistent responsibility patterns for certain task categories, with some variability in task categories like ‘Internal Management and Coordination’ and ‘Fabrication Support’.

- Detailer Responsibilities Pattern: The detailer consistently performs ‘Modeling & Shop Drawing Creation’ tasks, but shows the highest variability in responsibilities for ‘Internal Management and Coordination’ and ‘Fabrication Support’.

- Manager Responsibilities Pattern: The manager mainly performs and oversees tasks. They oversee ‘Modeling & Shop Drawing Creation’ tasks, perform ‘Internal Management and Coordination’, whereas perform and oversee ‘External Coordination’ and ‘Fabrication Support’ tasks.

- Coordinator Responsibilities Pattern: Coordinator functions as a more standalone role, often acting as a connector across teams, especially in inter-organizational settings. While frequently performing or being consulted in coordination tasks, the role shows limited involvement in ‘Fabrication Support’.

- Roles-Responsibilities versus Trades: MEP trades follow similar Task-Role-Responsibility patterns as shown in Figure 4.1, with supporting details in Figures 4.2 to 4.5 (Appendix X). Some variability exists, where certain trades show stronger or weaker patterns for specific task categories.

- Impact of Experience: Years of experience appear to influence understanding of job roles and team dynamics (Figures 4.6 to 4.9, Appendix X) indicating variation in the understanding of shared working practices across the project teams.

- VDC Department vs Executive Management: The VDC department and executive management show overall alignment in Task-Role-Responsibility perceptions, but some mismatches exist in understanding specific responsibilities, which may influence project performance.

Industry Implications

- Reducing Industry Fragmentation: Defining roles in the VDC Task Schema reduces ambiguity and promotes consistency, supporting better project management and workforce planning.

- Enabling Accurate Resource Allocation: Clear Task-Role-Responsibility understanding across VDC task categories helps prevent misallocation of resources, accurate task assignment and balanced team performance.

- Recognizing Time Allocation Variability: Tasks-Role-Responsibility mapping clarifies responsibility types, supporting time estimation and resource planning. However, varying roles and responsibilities across organizations create challenges for project managers in aligning team expectations.

- Clarity and Career Progression: Clearly defining VDC roles and their responsibilities strengthens job clarity, communication, and collaboration. It also supports performance evaluation, accountability, and career development within teams.

- Industry-Wide Benchmarking: Tasks-Role-Responsibility mapping provides industry-wide benchmarking opportunity. This shared framework supports performance comparisons, encourages best practice sharing, and drives overall industry improvement.

- Industry Wide Advancement: Structured Task-Role-Responsibility mapping encourages the MEP industry to address fragmented role-responsibility definitions and improve task alignment. It supports clearer project execution, better team coordination, and progress toward standardized industry benchmarking.

Practical Recommendations

- Optimize Resource Allocation: Adopting the Tasks-Roles-Responsibilities mapping helps redefine task, resource, and time allocation by recognizing different responsibility types, leading to clearer expectations and improved management of VDC tasks in the MEP industry.

- Foster Team Adoption: Implement Tasks-Roles-Responsibility mapping as a team in the VDC department of MEP industry to improve workflow, communication and collaboration.

- Clarify Role for Growth: Clear Task-Role-Responsibility expectations leads to clear job roles and career progression that will attract talent to the MEP industry.

- Customize per Trade: Refinement and adjustment of Task-Role-Responsibility mapping to a particular trade supports industry wide national benchmarking for MEP trades.

Assessment of Automation Levels in the Fabrication Process

Better Understanding of Automation in Fabrication

- Task Automation: Subcontractors automate fabrication support tasks by streamlining drawing production, documentation, and bill of materials preparation. They use in-house tool palettes, address interoperability issues between software packages, and make decisions about using off-the-shelf products or developing software in-house. These efforts are embedded within model-based workflows that go beyond 3D coordination and shop drawing creation.

- Drawing and Documentation Typologies: All respondents consistently use various drawing types—such as shop drawings, fabrication drawings, spool sheets, material lists, and as-built drawings. While shop and as-built drawings are typically required contractually, others are used internally to support fabrication and field installation.

Industry Implications

Companies across the MEP industry operate at different levels of automation, with electrical firms on the lower end. Higher level of automation is achieved through automating repetitive tasks, configuring interoperability, and model-based workflows. This spectrum of automation level might influence Task-Role-Responsibility mapping and time allocation, thus resulting in variability in the MEP industry.

Practical Recommendations

Multiple opportunities exist to improve VDC performance in the MEP industry through technology and process upgrades. Companies are using customized off-the-shelf/in-house tools, and model-based workflows to enhance information detail, reduce redundancy, and integrate systems—an attempt toward holistic improvement supported by clear Task-Role-Responsibility mapping.

4. Ongoing Efforts toward National Benchmarking Metrics

4.1 Tools for Creating Metrics

4.2 Industry Implications

- Operational Insight: The tools provide a structured way to visualize how VDC teams allocate time, helping identify high-effort tasks and guide decision-making.

- Flexibility & Inclusiveness: Customizable task selection makes the metrics adaptable to different company structures and project scopes.

- Benchmarking Foundation: Standardized time data allows for meaningful internal evaluations and cross-company comparisons to inform best practices.

4.3 Practical Recommendations

- Create Company Benchmark: Use historical project data to set performance baselines, track improvements, and guide long-term strategy.

- Benchmark Ongoing Projects: Apply metrics in real-time to detect performance gaps early and support proactive project management.

- Industry-wide Benchmarking System: Promote secure, anonymized data-sharing under a trusted framework to enable large-scale benchmarking and collaborative growth.